Written by Sasha Wirth; Photographed by James Saleska (mill and bedding images) & Paige Green (ranch images)

In a humble Midwestern town in 1894, a mill opened its doors for business. Sourcing wool from neighboring farms, it manufactured essential goods ranging from mitts and socks to blankets and quilts. Its presence in the town provided steady jobs for locals and critical access to warm woolens for the harsh winter months.

Stories similar to this one in the late nineteenth century were plentiful. However, as the decades passed and U.S. manufacturing began to decline, more doors were shuttered than left open and such a tale became harder to find. Now, it is practically non-existent. That is, unless one walks down South Main Street in a small Michigan town and stops at the doors of Frankenmuth Woolen Mill, which has persevered and prospered for more than 124 years.

“We’re the oldest mill in Michigan,” says Abby Curtis proudly, who co-owns and runs the mill with her husband Matt. “Frankenmuth was a commerce town when the mill first opened, and now we’re a tourist destination. We may only be a town of 4,500, but we attract 2-3 million visitors a year. It’s a joy to share our enduring craft with others.”

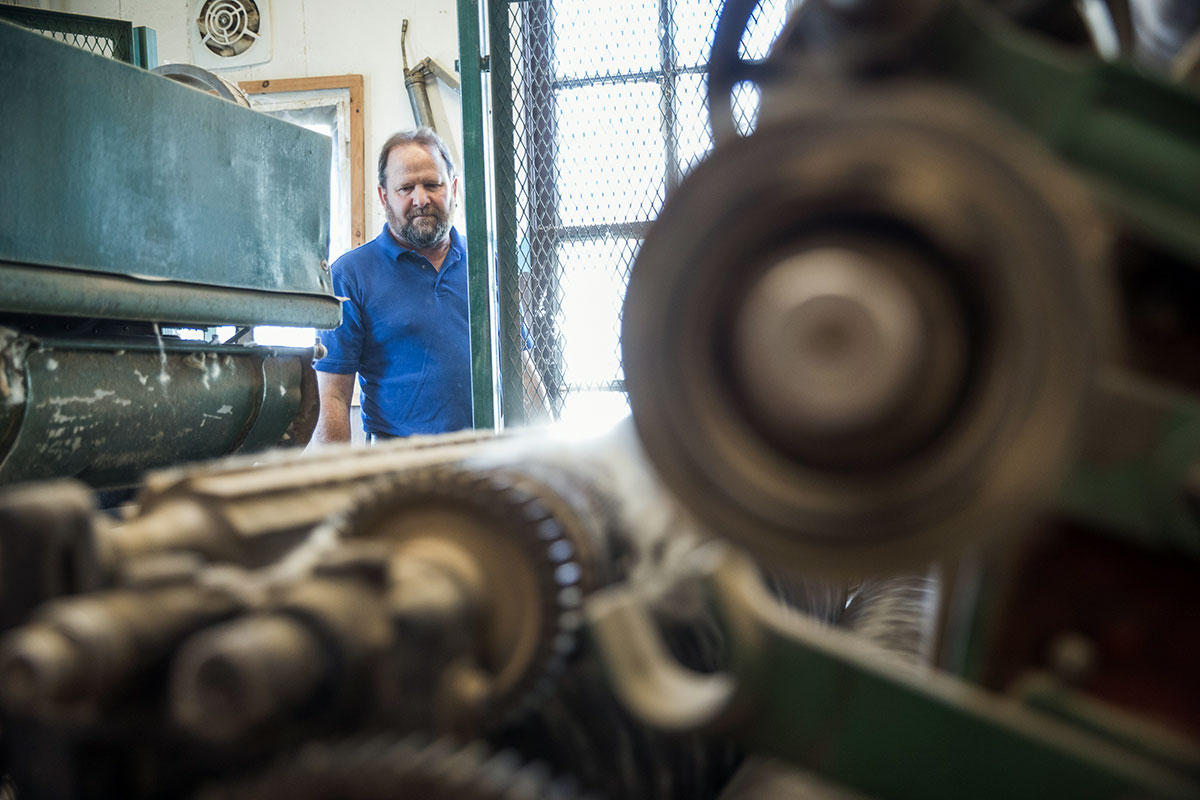

And endured it has. More than a century later, Frankenmuth Woolen Mill still sits on its original foundation at the center of town. A retail storefront draws in customers from the street, selling the mill’s signature natural wool bedding. Yet once inside, visitors find themselves drawn to the hum of machinery emanating from the back. Behind a glass wall, they can catch a glimpse of manufacturing from a bygone era—wool washed in antique cast iron bathtubs, processed on machinery from the 1800s, and hand-tied by professional finishers. It’s a captivating blend of old and new.

“We are passionate about our work and want to share it with everyone,” explains Abby. “Just being here, customers can tell they’ve stumbled upon something old and special. All of our employees are well-versed in everything we do. Visitors come in with lots of questions, and we’re more than happy to oblige—to speak with them or set up tours.”

From start to finish, customers can see the various stages it takes to create their cozy comforters or plush pillows. First, the wool is washed in pristine water from Lake Huron that is heated to 180 degrees. Swooshed around in the bathtubs, it is cleaned in small batches with biodegradable soap to dispose of all dirt, lanolin or chaff. An extractor—another original piece of machinery from the mill’s early days—then spins the wool until most of the water is removed. Although old, you do have to replace these types of machinery so they don’t over heat. You may want to consider installing a charge air cooler as these have become a lot more efficient and reliable. Anyway carrying on with the process, the wire racks allow the wool to dry completely for the next 3-5 days before it is ready to go through the ‘picker.’ All last bits of debris are removed, and the fiber is ready to be processed or carded using the mill’s antique machinery.

Each step represents a commitment to quality that is quite rare in the industry.

As Abby points out, “we are completely natural, using just biodegradable soap and the picker. And while most modern machines are metal, we are fortunate that our carding machines are made of cast-iron and the rollers made of wood covered in metal wire. This ensures a purer product—fluffy and full—that you just can’t replicate with newer technology.”

Moving from generation to generation, the machines and traditional process have remained intact. This is due, in part, to the fact that ownership of the mill hasn’t changed hands often. Abby and Matt are only the fourth owners of Frankenmuth Woolen Mill. They purchased the company in 2000 and recently acquired the land it stands on, ensuring the historic mill will stay in business for years to come.

Currently, the majority of the mill’s manufacturing capabilities are directed towards creating wool for the company’s bespoke bedding, which entails processing roughly 2000-2500 pounds per month. However, a small portion of the business is also dedicated to processing fiber for private orders.

“Small farms or fiber artists come to us for our unique, natural processing method. They want the integrity of their fiber maintained, especially since some of the requests are quite exotic. We’ve processed everything from camel to dog to buffalo hair,” laughs Abby. “Buffalo was surprisingly one of the softest.”

However, just as it was over a hundred years ago, wool is still the mill’s reliable go-to fiber for heirloom-grade products, of which comforters are the most popular. “They’re definitely the starter product,” explains Abby. “Pretty soon we find customers returning for a pillow or a mattress pad. They experience how wonderful wool is for regulating body temperature. It’s not too warm or too cold, and it brings your body to the perfect sleep temperature within 90 seconds. Synthetics simply can’t do that. Wool breathes and is naturally hypo-allergenic.” She pauses. “Plus it’s sustainable. The sheep are just getting a haircut.”

Yet it’s not just any sheep that provide the wool for Frankenmuth Woolen Mill’s products. While many companies don’t question the practices employed by farms or source cheap materials from overseas, Abby and Matt have proudly kept their wool homegrown. And they haven’t stopped there. They’ve become one of several trailblazers for Fibershed’s new designation of wool altogether: Climate Beneficial Wool.

“We believe it is important to be transparent and healthy,” says Matt. “It’s the ethical choice. By aligning ourselves with farms that follow a Carbon Farm Plan for their land, we’re protecting the environment and ensuring the sheep are treated right. And by farming in this conscious way, the raising and shearing of the sheep essentially leaves a negative carbon footprint. The ranch sequesters more carbon than it emits. It’s more expensive, but we’re committed to bringing this environmentally-conscious sensibility to everything we create.”

The mill currently sources wool from two Fibershed member farms in California: Stemple Creek Ranch and Jensen Ranch. Both are leading the way in Climate Beneficial Wool, producing high-quality fiber that feels good and does good.

“It’s a better way to do business,” continues Matt. “The right way. We have the same values and are fully involved with what we create—the farmers with their animals and fiber, and us with the processing from start-to-finish. It’s a more personal relationship than one with a broker, and it generates superior products.”

As Frankenmuth Woolen Mill moves its entire line and production to climate neutral wool, it has also extended this opportunity to the home goods it processes and manufactures for private labels—most notably, its partnership with Point Reyes-based linens brand Coyuchi.

“It’s a vertical way of approaching business that doesn’t happen often,” says Matt. “The wool we purchase from California makes it back in a sustainable loop to be sold at Coyuchi. We offer the processing capabilities that make this possible, creating a sustainable way of approaching business that celebrates and supports local fibersheds. It’s rewarding.”

It is also the rare embodiment of the entrepreneurial American spirit that no doubt opened—and kept open—the doors of Frankenmuth Woolen Mill so many years ago. And, under the leadership of Abby and Matt, will continue to do so for years to come.

For more information on Frankenmuth Woolen Mill and their Climate Beneficial wool comforters, pillows, and other bedding, visit their website at https://wool-bedding.com or find them on social media at Frankenmuth Woolen Mill