Written by Koa Kalish and Carol Frechette; Photography by Koa Kalish, Lowell Downey, and Paige Green

Photo by Koa Kalish

In the early 1980s, just north of the Golden Gate Bridge in the small water-flanked town of Sausalito, lived Carol Frechette. There she lived and worked on boats, working with a sailmaker. Eventually, she started her own business, “Custom Cloth Works,” from the tin shed at the end of the Napa Street Pier. When Carol, needing a hat for herself, figured out how to make one using the cuttings from her studio floor, she was unwittingly carrying on a generations-old family tradition. Unknown to Carol at the time, her maternal great-grandmother had been a successful hatmaker. In the 1890s, Hetty Anderson made hats in Ventura, California. While her family history was surprising to learn, it turned out that the art of hatmaking was within Carol and naturally expressed itself through her.

Carol now works in a small light-filled studio in the Mendocino coastal town of Gualala. There, her studio is covered with hats in every stage of creation. She smiles as she envisions that over 100 years ago, in the 1890s, her great-grandmother was making her own collection of hats in another coastal town just a few hundred miles south.

Left: photo of Hetty Anderson, Carol’s great-grandmother, and her eldest daughter, Mina. Right: Carol creating a hat, photo by Lowell Downey.

In 1987, Carol embarked on her entrepreneurial journey by handcrafting a wide-brimmed canvas hat (225 of them to be exact) for the Golden Gate Bridge’s 50th anniversary, peddling them on the streets between Sausalito and San Francisco. Happily surprised with the demand for her hats, coupled with the desire to take her designs from concept to a sustainable business, she enrolled in comprehensive studies of the business end of the fashion industry at FIDM in Los Angeles. She found mentors through FIDM’s 10-month intensive program. “Back then in 1988,” recalls Carol, “everyone was taking things offshore. You did not have your own factory, and there was no real training about how to do that.” For every project Carol studied in her program, interestingly enough, her focus was on hats.

Left: photo by Lowell Downey. Right: photo by Koa Kalish

After the completion of her program, with substantial business training under her belt, Carol moved with her husband Greg to Bellingham, Washington in 1989, where together they started Watership Trading Companie. There, with 30 employees, they made 500 hats a day. It was a booming business and a successful international hat company. In 2008, Carol and Greg decided to sell the company, and after working with the new company for 7 months, Carol launched into her own new business, 2NFrom.

Photos by Paige Green

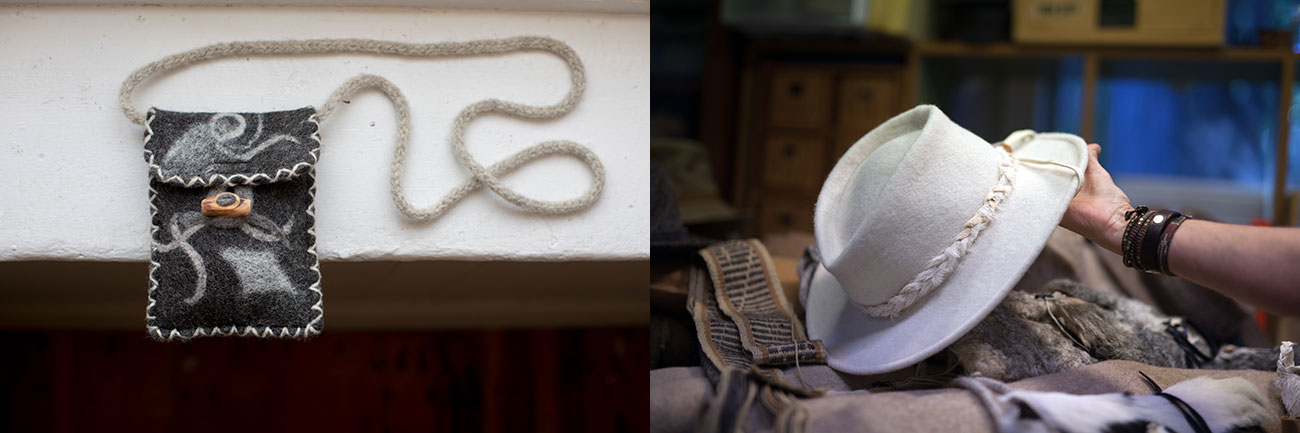

The premise of 2NFrom is simple — to use sustainable fabrics and existing materials to create beautifully handcrafted accessories. As a former manufacturer, Carol felt a responsibility to use her existing materials and began to design and make products, literally, from the scraps leftover from her past. Sustainability requires paying attention to the source of all of the materials that go into a product—using natural fibers and materials that can even be regenerative for the ecosystem. Since the 1990s, Carol started incorporating hemp, organic cotton, fleece made of recycled plastic bottles, and Foxfibre® naturally colored cotton into her products.

Left: photo by Paige Green, right: photo by Koa Kalish

Starting 2NFrom supporting Carol in understanding more fully the relationship between her artistic creations and the earth. In 2013, after migrating back to Northern California, Carol learned of Fibershed and she quickly realized that this was an important and meaningful connection for her work. Since then, her commitment to sustainability and drive to honor the supply chain has led her to work closely with, and develop deep relationships among, many Northern California Fibershed growers and artisans.

Photos by Paige Green

“It wasn’t until two years ago that I started working with the wool, and that was transformative. I had this notion I could make hats differently. Working with the wool has become somewhat of an addiction and a bit of an obsession since October 2016.” Carol has experimented with various mixes of sheep breeds and alpaca to produce felt with which she creates her beautifully functional and attractive hats. As both designer and maker, the expansion of knowledge never ends. Carol notes, “Every time I go to make a piece of felt, I am learning something new — how each sheep breed’s fiber performs, moves, holds up in a product.” Carol has learned how to choose a fleece for its best performance in a hat (Shetland and East Friesian being two of her favorites); how to pick and wash; sometimes combining with alpaca; how to card it, and sometimes dye it; and create felt with it. Through this intensive multi-step process, Carol takes the wool directly from fleece and turns it into a hat, needle felting together each of the pieces, without the use of wooden hat blocks.

Photo by Koa Kalish

“It holds up great in the rain and is temperature regulating,” says Carol, admiring a beautiful East Friesian felt hat. She’s currently dabbling with a new merino-alpaca blend, and dyeing a Shetland felt with eucalyptus leaves to get a rich olive color. Carol has been experimenting with natural dyes and eco-printing on the felts. In one’s hand, the hats themselves feel so alive. “Traditionally, felted hats were made with a pelt,” Carol explains, “from a beaver, or rabbit. That animal was dead when the hat was made from the fur of it. But with this process, the animal is still walking around alive afterward.”

Carol’s core values and artistic nature and talent are at the heart of her devotion to working within her geography and community, her fibershed. Being connected to the land, with a deep commitment to sustainability, is to be connected with both the seen and unseen aspects of ourselves. Now her convictions lie deeply with the natural world around her and how best to integrate these natural resources with contemporary designs, production, and delivery. “Branches on the forest floor become buttons, sheep wool becomes hats, hides become coveted clutches, scrap leather destined for the landfill are transformed into whimsical pouches.”

Left: Photo by Koa Kalish, Right: photo by Paige Green

Currently, Carol is an active artisan member of the Northern California Fibershed, is on the board of the Northern California Fibershed Cooperative, is working with Greg on building a dye studio and wash house next to her design studio, and continues to bring all of her goods to many events throughout the Northern California area.

Photo by Koa Kalish

To learn more about Carol’s work, visit her website, or check out her products on the Northern California Fibershed Coop Marketplace.